Precision, speed and an impeccable finish

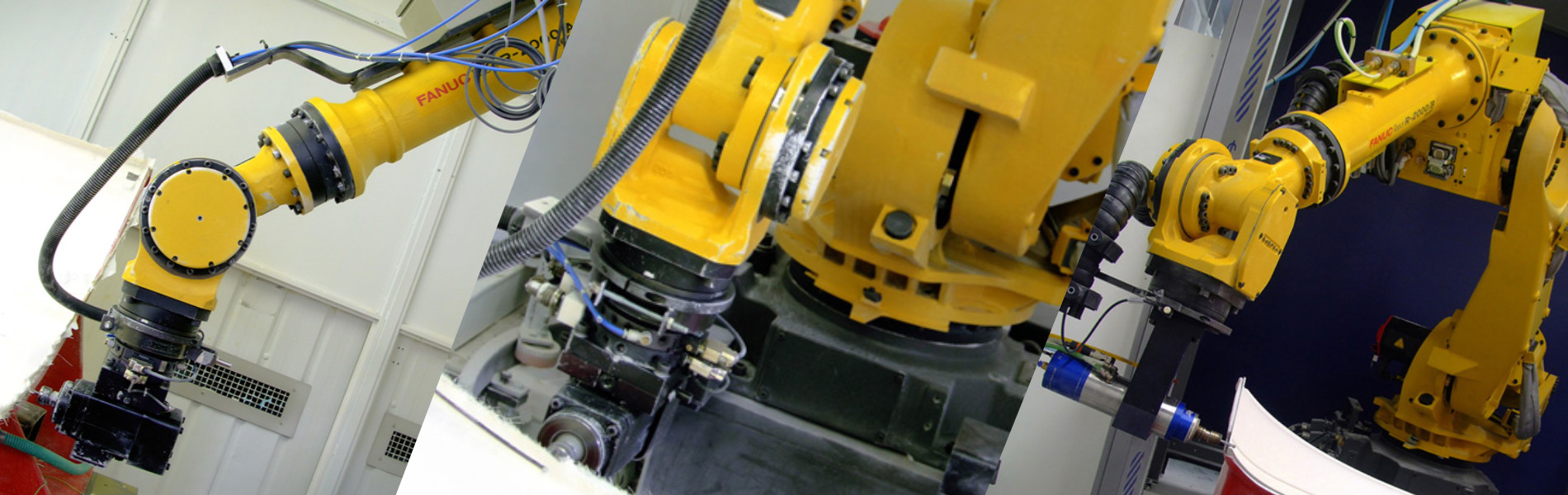

Where accuracy and consistency are priorities, robotic trimming offers the most economic solution. Broadwater employs two multi-station robotic trimming centres providing repeatable accuracy and high throughput.

The investment in robotics allows the trimming of more than 70% of FRP mouldings currently manufactured by Broadwater. The aim is to further develop its worldwide business and strategic position in the targeted segments of Automotive, Medical and Industrial as well as exploring other markets.

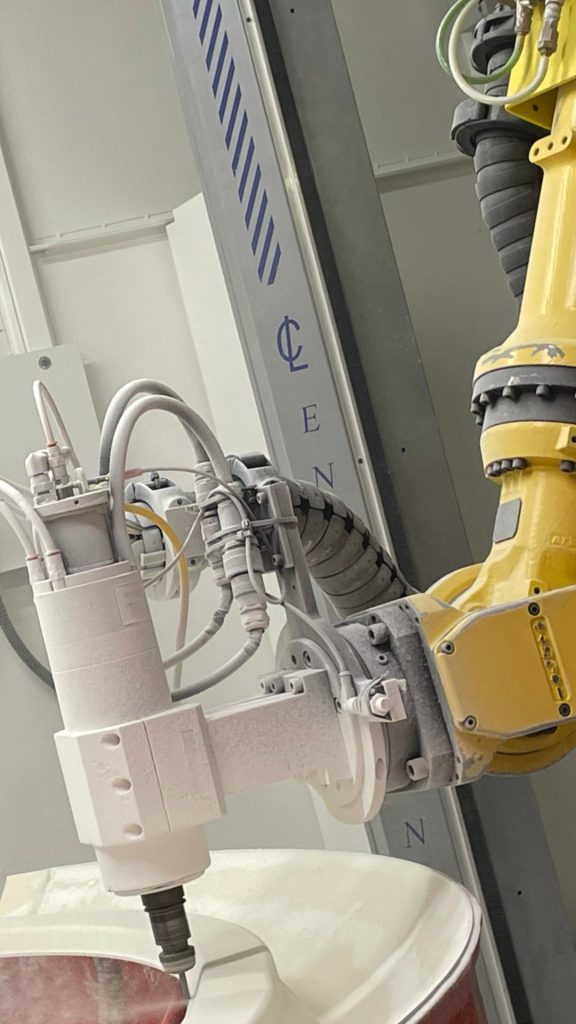

Broadwater Mouldings have two 5 Axis CNC Robot Trimming Centres, installed, completed by Fanuc, who Broadwater Mouldings have worked with for over 15 years. The system has one fixed spindle which has 6 chucks currently but more can be added to suit new work. The tool centre point is proven to be more accurate over long term tests compared to the spindle change system that older cells used. With the spindle in place both centres can potentially offer customers a considerably less expensive part than manual trimming, particularly on complicated trim conditions.

For further assitance, or for more information please contact us.